Center for Drug Evaluation

July 2024

I. Introduction

Polysaccharide conjugate vaccines refer to polysaccharide-protein conjugate vaccines prepared by chemically or otherwise binding the polysaccharide antigens of pathogenic microorganisms to carrier proteins, used for enhancing the immunogenicity of bacterial vaccine polysaccharide antigens, e.g., Haemophilus influenzae type b polysaccharide conjugate vaccine, meningococcal polysaccharide conjugate vaccine, and pneumococcal polysaccharide conjugate vaccine. Bacterial polysaccharides are Thymus independent antigens (TI-Ag), and polysaccharide conjugate vaccines can endow polysaccharide antigen components with Thymus dependent antigen (TD-Ag) characteristics. The induced antibodies can enhance the clinical efficacy of the vaccines through such functions as isotype switch, affinity maturation, and immune memory.

The polydispersity of polysaccharide molecules, the randomness of activation and binding sites, and the impact of chemical reactions on sugar chains determine the heterogeneous characteristics of polysaccharide antigen intermediates and conjugate bulks. In the meanwhile, the production of polysaccharide conjugate vaccines involves multiple process steps, and the existing forms and antigen epitopes of polysaccharides and protein carriers may all change in each process step and play a role in the next reaction steps. Therefore, throughout the pharmaceutical development process, it is needed to give consideration to the impact of process steps on the antigenicity, uniformity and process controllability of each intermediate, strengthen technical control and process control, conduct comprehensive process research and validation, verify the impact of process parameters on quality attributes, and ensure batch-to-batch consistency and process robustness. It is recommended to also give consideration to variation trends of polysaccharide/protein structures and biological activity throughout the process and use multiple analytical and strategies such as physicochemical structural analysis and immune response characterization to comprehensively improve the development level and quality control of such products. It is also encouraged to accumulate relevant study data on structure-activity relationships.

The comprehensive structural analysis of polysaccharide conjugates is still facing technical challenges, so a comprehensive quality control system including process characterization, process control and use of multiple analytical methods should be established. The quality control of polysaccharide conjugate vaccine is typically performed using combinations of physicochemical methods and immunochemical methods and using these methods in combination. A system of sensitive and strongly specific methods should be established, and appropriate methods should be selected depending on product characteristics of different process stages; for low contents or methods requiring pretreatment, it should be ensured that the testing process can reflect the true state of the product; for such testing methods as assay of polysaccharides, if methods of different principles are used at different manufacturing stages, it should be ensured that the two methods are relevant.

Recent years has witnessed the progress of technologies and studies on mechanisms of action (e.g., B cell epitopes, T cell epitopes, etc.), and future research on polysaccharide conjugate vaccines will include the development of new pathogens, the development of higher-valence multivalent vaccines or combined vaccines, the development of new protein carriers containing more T cell epitopes or additional functions, and the development of new conjugation methods (e.g., bioconjugation, click, etc.).

This guideline applies to chemically prepared covalently bound polysaccharide conjugate vaccines and combined vaccines developed using them as components. For multivalent vaccines and combined vaccines containing polysaccharide conjugate vaccines, relevant guidelines on combined vaccines should also be referred to in conducting pharmaceutical studies. For conjugate vaccines manufactured using new protein carriers and new technical routes for conjugation such as genetic engineering expression, multiple antigen-presenting system (MAPS) non-covalently bound polysaccharide conjugate vaccines and polysaccharide conjugate vaccines manufactured using other technologies, appropriate studies should be conducted based on the relevant characteristics and attributes of the products when referring to this guideline.

Pharmaceutical studies for polysaccharide conjugate vaccines should comply with relevant requirements of the Drug Administration Law of the People’s Republic of China, the Vaccine Administration Law of the People’s Republic of China, the Drug Registration Regulations and the Pharmacopoeia of the People’s Republic of China. The production of samples for clinical trial use should comply with relevant requirements in the annex on investigational drugs (interim) in the current Good Manufacturing Practice. This guideline should be used together with other domestic and foreign guidelines.

II. Bacterial Seeds and Seed Lots for Production

Bacterial seeds for manufacturing polysaccharide conjugate vaccines include bacterial seeds for manufacturing polysaccharide antigens and bacterial seeds for manufacturing carrier proteins. Bacterial seeds for manufacturing carrier proteins include naturally isolated bacterial seeds and genetically modified bacterial seeds. For genetically modified bacterial seeds used in such technical routes as biological synthesis of polysaccharide conjugate vaccines, it is recommended to conduct more comprehensive studies based on product characteristics.

(I) Bacterial seeds for production

Bacterial seeds for production should comply with relevant provisions of the Pharmacopoeia of the People's Republic of China. The sources of bacterial seeds for production should be specified, and study dossiers on sources, histories (including isolation, identification, pedigree charts, etc.), construction process, characteristics and types of bacterial seeds for production should be provided with reference to requirements of the Pharmacopoeia of the People's Republic of China and relevant guidances. Strains for manufacturing polysaccharide antigens should be characterized and identified in combination with structural characterization of polysaccharide products. When necessary, the configurations of polysaccharide products should be characterized using such means as nuclear magnetic resonance (NMR).

(II) Seed lots

Seed lots should be established in accordance with the relevant provisions of the Pharmacopoeia of the People's Republic of China and/or international requirements. The corresponding testing reports issued by national drug control institutions should be provided.

Manufacturing and testing records of seeds at all levels should be provided, seed expansion culture media and culture conditions, passage methods, preparation scales and preservation methods should be specified, and the passage number should be strictly limited. With regard to the testing of seed lots, test items should be determined based on specific strains, typically including culture characteristics, staining microscopy, biochemical reactions, immunological tests, pure culture test, etc.; as to seed lots for toxoid production, toxin production tests and specific neutralization tests should be additionally included. The testing of seed lots for manufacturing recombinant carrier proteins expressed using recombinant genetic engineering technology should also include the investigation of relevant metrics such as the genetic stability of the expression system, the expression stability of the target gene, and production stability.

Stability studies include storage stability and passage stability. The storage conditions and shelf life of seed lots should be established through storage stability studies, and the passage number limits for seed lots at different levels should be established based on passage stability studies. Passage stability studies should include simulated passage stability studies and passage stability studies for actual manufacturing processes. In addition to routine release tests on seed lots, for protein seed lots constructed by genetic engineering, sequencing study data of target genes and key components of both wings should be provided insofar as possible in the clinical trial applications, and consideration should also be given to the genetic stability of sites related to such functions as carrier protein attenuation. With regard to seed lots for manufacturing polysaccharides, as the expression of polysaccharide antigens does not follow the genetic central dogma while their expression and structures are subject to influence by relevant enzyme genes, the passage stability of polysaccharide expression and structure related genes should be studied. Studies on molecular genetic characteristics of product expression related genes should have been completed before submitting the marketing application, and it is recommended to further evaluate the passage stability and commercial production applicability of seed lots based on structures of polysaccharide antigens.

III. Culture Media and Raw Materials for Production

All biological and chemical raw materials used in the production of polysaccharide conjugate vaccines are closely related to the safety, efficacy and batch-to-batch consistency of the products, including materials used or added during production (e.g., culture media and additives, purification reagents, coupling reagents, etc.). Quality control should be conducted based on the principle of risk assessment in accordance with relevant requirements such as the Pharmacopoeia of the People's Republic of China. Some raw materials will have a significant impact on products’ reaction kinetics, batch-to-batch consistency and immunogenicity and thus warrant full assessment, appropriate pretreatment or other appropriate control measures.

For animal derived materials (including those used in the preparation process of cell banks/seed lot systems) and critical complex raw materials, their sources, characterization (if applicable), specifications, and stability should be specified, and exogenous agent safety (including TSE/BSE risks) should be assessed. For raw materials for production/intermediate products that may introduce toxicity, safety risks should be fully evaluated. With regard to the composition of culture media, use of animal derived materials should be avoided as much as possible, and use of bovine derived materials from areas affected by mad cow disease is prohibited. It is encouraged to minimize or avoid the use of animal derived raw materials.

IV. Manufacturing Process

(I) General requirements

Process development for polysaccharide conjugate vaccines should follow the quality by design philosophy. Quality target product profiles (QTPP) should be designed based on characteristics of polysaccharides, carrier proteins and conjugates, and process routes should be reasonably designed based on the comprehensive consideration of such factors as clinical expectations (intended clinical use, dosing system, dosage strength, etc.), quality characteristics, process route match, process controllability and operability, etc.

Overall, process parameters should be studied and optimized in a manner focusing on expected critical quality attributes of intermediates and finished products and process characteristics. Throughout the manufacturing process, it should be ensured, to the extent possible, that antigenic determinants, structures or specific groups of polysaccharide molecules are not significantly damaged and the expected immunogenicity is achieved. Consideration should be given to the effects of different process steps and process parameters throughout the process on molecular sizes, antigenicity, specific functional groups, etc., in order to provide a scientific basis for the establishment of process routes and parameters. It is recommended to fully study and characterize critical process parameter ranges and quality attribute ranges with physicochemistry and animal in vivo immunogenicity as investigational metrics to ensure the controllability and robustness of the proposed process, and to ensure the comparability of product safety and efficacy within the proposed process parameter and specification ranges. In process studies on representative types, the choice of representative types should be justified, and consideration should be given to differences between types and the applicability of the proposed process to different product types.

During process studies and process development, critical process parameters and their control ranges should be established, optimized and qualified, and process control strategies should be gradually clarified. Reasonable process control items and limits can be proposed based on process control information in process development and in the production of multiple batches of intermediates and drug products.

Compared with clinical study batches, nonclinical study batches should be to a sufficient extent representative. The preparation process of clinical study batches should be implemented at a sufficiently large scale with appropriate production continuity and scale-up feasibility. It is suggested confirmatory clinical study samples be consistent with products for marketing in manufacturing process, scale and site; for changes during clinical studies, full comparability studies should be conducted with reference to domestic and foreign relevant technical guidances.

The content of commercial manufacturing process validation should be determined by means of risk assessment based on the product’s manufacturing process and quality attributes. Generally, process consistency, the robustness of critical process parameters, the removal of product related impurities and process related impurities and the batch-to-batch consistency of product quality should be included. Process validation should include additional sampling points and test items on the basis of routine process controls and release test items to investigate the consistency of process controls, intermediate products and finished products and the process robustness. It is suggested that extended validation items include but not be limited to molecular weights and molecular weight distribution of products at different process stages and the retention of specific functional groups.

Moreover, the production of polysaccharide conjugate vaccines typically comprises a series of chemical reactions such as polysaccharide hydrolysis, polysaccharide activation or derivation, polysaccharide conjugation, and blocking of unconjugated activation sites. Polysaccharides and proteins involved in the reactions are all macro-molecular substances, and each process parameter may have an impact on the final outcome. The consistency of reaction processes largely determines the consistency of product quality. It is recommended to conduct reaction kinetic studies during process research, qualification and validation, so as to evaluate the consistency of reaction processes for better controlling product quality.

The production of polysaccharide conjugate vaccines can be divided into different stages (polysaccharide production, conjugate production, etc.) and process types. At the marketing application stage, the production structure and mode should be fixed, and comprehensive process validation should be completed. Differences in polysaccharide properties and other aspects result in incompletely consistent process parameters for different groups/types. The strategy of using bracketing/matrixing approaches for process validation should be carefully evaluated, and commercial process validation protocols should be reasonably developed. Prior to marketing, validation on at least three consecutive batches should have been completed for each type. After marketing, continuous process validation should be conducted during commercial production.

(II) Polysaccharide antigens

The manufacturing process of polysaccharide antigens typically comprises three stages, i.e., fermentation, sterilization, and purification.

Culture media and fermentation processes should be reasonably selected based on the growth and metabolism of bacterial seeds and the biosynthetic routes of products. The composition and pH of culture media, inoculation ratio, fermentation process parameters (temperature, aeration, dissolved oxygen, rotational speed, tank pressure, etc.), feeding time points and fermentation endpoint should be studied and optimized; the passage number, preparation conditions and fermentation endpoint should be clarified; studies on the consistency of bacterial growth and polysaccharide expression across different batches or different culture tanks should be enhanced; typically, investigational metrics include cell density at the harvesting endpoint and the crude saccharides production per unit volume of culture media. It is suggested studies on bacterial growth curves and polysaccharide expression curves be conducted to reasonably determine the fermentation endpoint. After the end of bacterial fermentation, sampling should be performed for pure culture test to demonstrate that the fermentation process is pure culture.

With regard to the sterilization process, the type and concentration of sterilizing agent and sterilization conditions (temperature, duration, bacterial concentration, antigen concentration and purity, etc.) should be studied and optimized. Sterilization effects and sterilization kinetic curves should be studied and validated. If the sterilization process is a bacterial autolysis process, product related impurities such as C polysaccharide may occur. It is suggested the sterilization process be studied to investigate the impact on polysaccharide quality and structures and qualified on process validation batches.

Purification is often achieved by precipitation (organic solvent precipitation, denaturing precipitation, surfactant precipitation, etc.), filtration (depth filtration, carbon filtration, etc.), chromatography, ultrafiltration, etc. The purification process route should be designed reasonably based on the characteristics of the product. Critical parameters including target product concentration, temperature, flow rate, reagent formulation and concentrations, pH value, ionic strength, processing time, pressure, and loading capacity, as well as their control ranges should be studied and optimized; the impact of each process parameter on critical quality attributes of polysaccharide antigens should be investigated, e.g., molecular size, functional group changes, impurity residues, etc. The recovery rate of the target product and the removal rate of product and process related impurities should also be studied. Process parameters and process control strategies should be established based on study results. The established manufacturing process should be fully validated. In addition to routine release metrics, the process impurity removal rate of each process step should be validated. It is encouraged to use advanced means such as NMR for additional characterization. If the strain for production is a Gram negative bacterium, the manufacturing process should include a fully validated process step for removing endotoxins.

(III) Carrier proteins

Carrier proteins include multiple types such as tetanus toxoid, diphtheria toxoid mutant, bacterial outer membrane proteins, etc. Different protein carriers vary a lot in quality attributes, abundance of binding sites, immunogenicity, etc. Dossiers including the justification for the choice of carrier proteins and the superiorities of carrier proteins should be provided. Carrier proteins should effectively transform the polysaccharide antigen from TI-Ag into TD-Ag, stimulate the body’s humoral and/or cellular immunity and induce immune memory without causing severe hypersensitivity reactions. The varieties, structures, purity and amino contents of carrier proteins will all affect the conjugation reaction efficiency and the conjugate immunogenicity and safety. Carrier proteins should be selected based on the comprehensive consideration of the impact of carrier proteins on the safety and efficacy of conjugate vaccines as well as the bulk manufacturing process, quality control strategies and the feasibility of scale production. For multivalent and combined vaccines containing conjugate vaccine components, potential immune suppression, immune interference and safety following vaccination should be fully assessed and studied based on total protein contents of finished products and number of immunization doses to reasonably select the varieties and added amounts of carrier proteins.

The manufacturing process of carrier proteins mainly includes such process steps as fermentation and purification. Process routes should be reasonably selected to ensure protein amino contents and monomer protein purity complies with requirements of the conjugation process. Process studies can be conducted with reference to relevant guidelines for toxoids and genetically engineered recombinant proteins to establish comprehensive process control strategies; the removal effects of non-target proteins, protein aggregates and process related impurities as well as the binding site retention proportion in each process step should be studied. The detoxification process of toxoid carrier proteins will form protein aggregates and block activation sites such as amino groups, which does not agree with the consideration of using them as components of toxoid vaccines (e.g., tetanus vaccine). The detoxification process can be further optimized to retain as many activation sites as possible while ensuring complete detoxification. To ensure the uniformity and quality controllability of conjugates, the purity of carrier proteins should be maximized. It is suggested effective purification processes be developed based on traditional toxin manufacturing processes, so as to control the molecular sizes and distribution of toxins within a specified range.

(IV) Conjugate bulks

Based on multiple factors such as structures and characteristics of polysaccharide antigens, varieties of carrier proteins, principles of process routes, process controllability and immunogenicity of conjugates, appropriate process routes should be comprehensively assessed and selected on the premise that process feasibility, process controllability and immunogenicity are ensured, e.g., whether polysaccharide degradation, polysaccharide and/or carrier protein activation/derivation are needed, and whether connecting arms are required. In addition, consideration should be given to potential side reactions at each process stage and by-products that may appear in final products.

1. Polysaccharide degradation

Polysaccharide degradation can improve the uniformity, batch-to-batch consistency, and process operability of conjugates (e.g., reducing viscosity, etc.). In addition, degradation of some polysaccharide antigens can introduce binding sites (e.g., ortho-position hydroxyl groups, etc.). Polysaccharides are typically degraded by physical (ultrasound, mechanical shear) and chemical (hydrolysis, oxidation, etc.) methods. In addition, polysaccharide degradation may occur during some activation and derivative processes (e.g., sodium periodate oxidation, cyanide bromide activation, etc.). The molecular weights and distribution of degradation products will affect the immunogenicity of conjugates. As the breakage of sugar chains during the degradation process may affect the content of specific functional groups, the proposed molecular size and distribution ranges of polysaccharide degradation products should be justified, the degradation process route and process parameters should be studied and optimized with critical quality attributes such as molecular sizes and distribution and antigenicity of polysaccharide degradation products as investigational metrics, and studies on degradation kinetic curves should be conducted. During process validation, the removal effects of polysaccharides of non-target molecular sizes, the contents of specific functional groups, antigenicity and degradation kinetics should be verified.

2. Activation, derivation

Activation and derivation are processes of introducing new chemical sites by chemical modification of polysaccharide or protein molecules. Reactive groups on polysaccharide molecules that can be chemically modified include hydroxyl, carboxyl, phosphate, amino, and terminal aldehyde groups. Except the hydroxyl group, these functional groups can be derived without activation. Theoretically, the conjugation process using terminal aldehyde groups can form a single terminal connection, while other conjugation methods form network cross-links. Derivative sites on protein molecules are carboxyl or amino groups. At present, common activation and derivative process routes include cyanidation method, carbodiimide condensation method, reduced amine method, active ester method, etc.

During process development, the introduction and quantity of new chemical sites should be evaluated for their impact on antigen structures and antigenicity. Ranges of critical quality attributes including activation rate and derivation rate should be proposed based on process requirements and, on the basis of this, critical process parameters including antigen concentration, reaction solution system, added quantities of activation and derivation reagents, temperature, pH value and reaction durations should be studied and determined for chemical reactions, and studies on activation and derivation kinetic curves should be conducted to verify the relationships between process parameters and the activation degree or the derivation rate. For the chemical modification of polysaccharides, the effects of chemical reactions on the content of specific functional groups (e.g., O-acetyl group), polysaccharide molecule sizes, and antigenicity should also be considered. Parameter ranges should be established and effective process control strategies should be adopted. For the chemical modification of carrier proteins, the effects of the chemical modification process on the protein monomer content should be considered to avoid excessive cross-linking.

Effective purification processes should be selected to remove process related impurities, including activation reagents, organic solvents, quenching agents, unconjugated spacers, etc. A comprehensive evaluation and verification of impurities that may be introduced or generated during the production process should be conducted to determine the purification effect.

With regard to the validation of derivative and activation processes, it is recommended to validate the effects of chemical reactions on the content of specific functional groups (e.g., O-acetyl group), polysaccharide molecule sizes, and antigenicity apart from release testing; with regard to the validation of effects on protein monomer content and amino content, derivation and activation kinetic curve studies should be conducted on validation batches; the impurity removal effects should be validated.

3. Conjugation process

Conjugation refers to covalent or non-covalent conjugation of polysaccharides and carrier proteins. The choice of the conjugation process route should be justified, with the reaction mechanism specified.

During process development, critical process parameters and their control ranges should be studied and verified, including polysaccharide-protein feeding ratio and amounts, reaction pH, temperature, reaction duration, reaction ending conditions, etc. Studies on conjugation kinetic curves should be conducted, consideration should be given to the utilization efficiency of activation and derivation groups, the contents of unreacted groups should be studied, and reaction parameters should be optimized to reduce the proportion of unreacted groups. The purpose of each purification process step should be specified, critical process parameters of the purification process should be studied and verified and, depending critical quality attributes of conjugates, polysaccharide conjugates of different collected components should be assessed, so as to reasonably determine components for collection. For both the conjugation reaction and the purification process, corresponding process control strategies should be developed; reaction parameters and purification parameters should be monitored and controlled to ensure the conjugate quality.

Critical quality attributes including polysaccharide/protein ratio, total protein content, molecular sizes and distribution of conjugates, free polysaccharides, and free proteins all have an impact on immunogenicity. It is recommended to conduct animal immunogenicity studies that can cover the variable ranges of process and product quality attributes during the process development to verify the process robustness.

In addition to routine release test items, conjugation and purification process validation should account the recoveries of monovalent conjugate of target molecular sizes, removal rates of free proteins, free polysaccharides, unconjugated activation sites and process related impurities, etc. The conjugation kinetic curve should be validated; the process controllability should be validated by the free protein/free polysaccharide-time curves.

(V) Product formulation and manufacturing process

Polysaccharide conjugate vaccines include multiple forms such as adjuvanted vaccines, multivalent vaccines, combined vaccines, etc. Product formulations contain multiple components including bound antigens, free antigens, free proteins, etc., and multiple interactions between antigens, adjuvants and buffers/excipients may exist. The formulation of vaccine products may require multiple process steps including antigen preparation, buffer preparation, adjuvant preparation, antigen-adjuvant adsorption, semi-finished product preparation, lyophilization, etc. The formulation and process of the drug product should be specified and justified; sources, specifications and testing reports of excipients should be provided.

With regard to the product formulation, the role (including adjuvant, stabilizer, buffer system, surfactant, etc.) and content of each component should be specified and justified; the preliminary product formulation should be screened and determined based on the prior development and platform knowledge of similar products and the effects of different product formulations/processes on animal pharmacodynamic studies (immunogenicity, protectiveness studies), toxicological studies, manufacturing process controllability and stability, with corresponding justifications provided. With regard to the contents of antigens in multivalent/combination vaccines, the compatibility between different serotypes/antigens should be studied, and it is recommended to give consideration to potential immunogenicity interference. The antigen content should be preliminarily determined through nonclinical studies and early clinical studies, and verified in confirmatory clinical trials. The formulation (including formulation points, strength, etc.) of the product to be marketed should be consistent with confirmatory clinical samples.

With regard to product process development, preliminary study dossiers (including study methods, study results and study conclusions) should be provided to justify critical process steps and their parameter control ranges. With regard to the semi-finished product preparation process, such parameters as the addition order and added amounts of the bulk and excipients, the agitation speed and duration for mixing as well as temperature control should be studied and optimized. The conjugate integrity and batch-to-batch consistency of products should be ensured during the formulation process. For a freeze-dried product, such critical parameters as freezing temperature, freezing time, drying temperature, degree of vacuum for drying and drying time and their control ranges should be studied and optimized to establish the control ranges of the above parameters, and provide the freeze-drying curve; the impact of the freeze-drying process on the quality and relevant characteristics, and efficacy of conjugate vaccines before and after freeze-drying should be studied.

If addition of any adjuvant is needed, the reasonability and necessity of adding the adjuvant should be specified, and relevant study data on the variety and amount of the adjuvant as well as the optimal matching dose for the antigen should be provided. The potential benefits associated with the use of adjuvant must outweigh the risks. The complete set of pharmaceutical study dossiers of the adjuvant should be provided with reference to relevant study guidelines for adjuvants. In addition, the adsorption kinetic curve should be provided, and studies on the adsorption rate for each type of conjugate should be conducted during product development.

The product strength should be established based on polysaccharide conjugate vaccine process studies and validation, specification, stability testing and clinical trial results. In principle, product strengths of polysaccharide conjugate vaccines should agree with formulation points.

V. Quality Studies

Quality studies should be conducted on samples of representative batches (e.g., nonclinical study batches, clinical study batches and (or) commercial process batches, etc.) and/or at appropriate manufacturing stages. In addition to routine release testing and analysis, quality attribute studies should be conducted using appropriate analytical methods, typically including structural characterization, purity, impurity analysis (process related impurities and product related impurities), biological activity, etc. Comprehensive information should be provided as far as possible to reflect quality attributes of samples. It is encouraged to develop more advanced analytical methods based on product characteristics. Consideration should also be given to the treatment and analysis of samples. Analytical procedures such as sample pretreatment must not affect product quality, or the analytical results cannot represent the actual quality of samples.

(I) Product quality attribute studies

1. Quality attribute studies pertinent to sugar chains of intermediate products at different stages (refined polysaccharides, degradation products, activation products, derivatives, conjugate bulks, etc.)

The analysis of sugar chains is highly dependent on prior knowledge. For known polysaccharides, studies can be conducted with reference to domestic and foreign pharmacopoeias, technical guidelines, and relevant literature; for unknown polysaccharides, a complete structural analysis is required.

Quality attribute study items for refined polysaccharides, degradation products, activation products, derivatives and conjugate bulks mainly include monosaccharide composition, structure (identification, contents of specific groups), molecular size and distribution, conjugation status of sugar chains and protein carriers (conjugation method, ratio, amino acid utilization rate, etc.), residues of product related impurities and process related impurities, safety measures (bacterial endotoxins, sterility), etc.

Quality studies for polysaccharide degradation products are generally conducted by the same methods as those for refined polysaccharides and should account changes in corresponding quality attributes. Activation products and derivatives are chemically modified intermediates, and appropriate methods should be selected based on the physical and chemical properties of the activation and derivation groups to characterize the degree of modification. The range of the modification degree should be established based on physicochemical metrics and biological activity, and excessive modification of natural antigens should be avoided. Quantitative or semi-quantitative immunochemical methods (e.g., ELISA and rate turbidimetry) can be employed to investigate changes in antigen epitopes before and after polysaccharide antigen modification.

Quality attribute study items for monovalent conjugate bulks mainly include the polysaccharide/protein ratio, free polysaccharides, free proteins, the conjugation status of sugar chains and protein carriers, and the content of unreacted binding sites, etc. The polysaccharide/protein ratio, free polysaccharides and free proteins are associated with the immunogenicity of conjugates and also important measures of batch-to-batch consistency and should be assayed using appropriate methods. Following the conjugation of polysaccharides and proteins, some specific chemical groups are difficult to determine with the previously used methods, and other suitable and feasible methods should be employed whenever possible. Appropriate methods should be used to demonstrate that chemically modified polysaccharides or carrier proteins do not contain activated functional groups, or to residues of unreacted functional groups can be determined by monitoring blocking reaction products or detectable blocking reactions. The conjugation status is a difficulty of conjugate elucidation at present, and studies can be conducted using such methods as nuclear magnetic resonance (NMR), liquid chromatography-mass spectrometry (LC-MS) and amino acid analysis.

NMR can be employed for the complete elucidation of sugar chain structures in intermediates at different stages (refined polysaccharides, polysaccharide degradation products, polysaccharide activation products, polysaccharide derivatives, polysaccharide conjugates), including monosaccharide varieties, connection methods, modification groups, etc. The NMR elucidation of part polysaccharide conjugate samples is technically difficult, and it is recommended to constantly improve relevant tests during clinical studies.

NMR techniques include one-dimensional NMR spectrometry (hydrogen spectrum, carbon spectrum, phosphorus spectrum) and two-dimensional NMR spectrometry (1H-1H COSY, 1H-13C HSQC, 1H-13C HMBC), which achieve the complete elucidation of sugar chain structures through the integration and analysis of information about chemical shifts, integration and coupling constant. For known polysaccharides, at least one-dimensional NMR spectra should be provided, characteristic chemical shift ranges and corresponding protons or chemical elements should be specified. It is encouraged to carry out two-dimensional NMR spectrum studies. Quantitative NMR, integrating quantitative hydrogen spectrometry and quantitative phosphorus spectrometry, can efficiently determine the contents of polysaccharides, phosphorus, and various specific groups (uronic acid, aminohexose, methylpentose, O-acetyl, glycerol, and pyruvate groups) in refined polysaccharides and polysaccharide degradation products. Depending on polysaccharide structures and assay purposes, NMR instruments with sufficiently high detection performance should be used, and appropriate analytical methods and sample pretreatment means should be selected for comprehensive elucidation; comprehensive analysis and validation means should be established for NMR spectral elucidation.

It is encouraged to use high performance size exclusion chromatography-multiangle laser light scattering (HPSEC-MALLS) and density gradient centrifugation for studies on precise molecular weights, molecular sizes and distribution.

2. Carrier proteins

Quality attribute studies should be conducted depending on types and process routes of carrier proteins. Consideration should be given to quality attributes affecting conjugation reactions such as protein monomer content/uniformity, binding site content, etc.

For toxoid carrier proteins, uniformity and amino content should be studied in addition to the items required in the Pharmacopoeia of the People’s Republic of China. For recombinant carrier proteins, addition to purity, monomer content and binding site abundance, quality studies should be conducted per requirements for recombinant DNA protein products, including primary structures (amino acid composition, free thiol groups, post-translational modifications, sequence coverage, molecular weight, peptide mapping, amino acid sequencing, terminal amino acid sequencing, etc.), advanced structures (circular dichroism, etc.), charge heterogeneity (isoelectric point determination, charge variants, etc.), and molecular size variants (monomers, polymers, degradation fragments, etc.). The purity of carrier proteins is highly dependent on the analytical method. Methods that can well separate monomers and polymers should be selected, and studies should be conducted on the assignment of each peak component.

Some processes involve derivative carrier proteins. Effects of the derivation rate and the derivation process on the monomer content and purity should be studied, and it is encouraged to use appropriate methods such as peptide fingerprinting and amino acid analysis to analyze protein derivation sites.

3. Drug products

Studies should be conducted to investigate the effects of the formulation process on quality attributes and efficacy of conjugate vaccines, including studies on the effects of the formulation process on the stability of conjugates, e.g., changes in molecule sizes and distribution, particle sizes, and free sugar contents of polysaccharide conjugates; for multivalent vaccines or adjuvanted vaccines, comprehensive component compatibility studies should be conducted, including compatibility between multiple antigens, antigen-adjuvant-buffer systems, etc. For adjuvanted vaccines, the adsorption status, adsorption kinetics and adsorption rate of each conjugate type should be studied.

(II) Impurity analysis

Potential impurities generated during production or storage and/or discovered from stability study batches include process-related impurities and product-related impurities. For early phase clinical trial applications, potential product-related impurities (comprehensive consideration based on toxicological test results, literature data, previously accumulated scientific knowledge and relevant information of similar products is recommended) and process-related impurities can be listed based on sources, risks and safety levels of residues, etc.; main impurities should be monitored and analyzed and, when necessary, included into specifications and/or preliminarily evaluated for safety. Prior to the submission of the marketing application, further impurity analysis and studies including separation and identification should be conducted. Whether impurities will significantly increase during production and storage and their correlation with vaccine efficacy should be considered, and their safety risks should be assessed with reference to the philosophy of ICH Q6B to determine whether or not to include them into process controls or release specifications; for items to be included in the quality control system, the limit criteria should be strengthened with the gradual advancement of studies. For test items included in the Pharmacopoeia of the People’s Republic of China, corresponding criteria must be fulfilled.

Product related impurities refer to unexpected products derived from target products during production or storage, including bacterial heteropolysaccharides (C polysaccharides, etc.), protein aggregates, degradation products (heteroproteins, etc.), unconjugated products (free polysaccharides, free proteins, etc.), etc. For such product-related impurities as C polysaccharides, it is recommended to use such appropriate methods as quantitative NMR for determination.

Process related impurities refer to impurities generated from residues of various reagents that are not components of drug products added during production. Potential process related impurities should be identified based on raw materials for production and manufacturing processes and qualitatively and/or quantitatively analyzed depending on risks; safety risks of residual impurities should be assessed; when necessary, impurity residues with potential safety risks should be included into specifications for control. Considering that added reaction reagents are mostly active and part reagents are chemically instable, appropriate testing methods should be developed based on final molecular characteristics of reagents. For process-related impurities that are relevant to critical quality attributes of vaccines, if the testing cannot be performed on finished products due to product characteristics, appropriate intermediates (e.g., refined polysaccharides, conjugates, etc.) should be sampled and tested, and the testing results should accurately reflect the residual level in each dose of the finished product.

(III) Biological activity

Biological activity is an important measure of product quality and clinical efficacy. It can typically serve as an important reference for establishing process routes, critical process parameter ranges and finished product formulations during process development. It is also a sensitive indicator of stability.

In vitro antigen testing is a commonly used means in process development, process qualification and process validation. It is encouraged to establish appropriate standard serum for investigating the overall retention of antigenicity and overall immune epitopes of intermediate products at different stages during production. Nevertheless, attention should be paid to the quality of standard serum, especially the specificity, valence and storage stability.

In vivo efficacy studies include total antibody and functional antibody studies. It is recommended to conduct studies on correlations between polysaccharide contents, total antibodies and functional antibodies, and select appropriate efficacy methods for finished product quality control. Factors including experimental animal species and strains, immunization doses, immunization schedules and immunization routes will also significantly influence immune responses and thus require full investigation and optimization during test method development.

Besides, the development of new technologies may make it possible to use sugar chip technology to analyze the immune activity of sugar chains in intermediate products and use monoclonal antibodies to analyze immune epitopes of sugar antigens. Such structures as non-specific polysaccharides, linker arms, or excessively damaged sugar chains during production may lead to unexpected immunological reactions. It is encouraged to carry out relevant studies.

VI. Specifications

Specifications may be established with reference to the Pharmacopoeia of the People’s Republic of China, ICH Q6B as well as domestic and foreign relevant guidelines based on characteristics of polysaccharide conjugate vaccine products, manufacturing processes, quality study data at each stage, batch release testing results and stability study results and with the comprehensive consideration of nonclinical and clinical study batches. In principle, they should not be less stringent than national standards and specifications for marketed similar products. For general process-related impurities, if it has been fully validated that they can be effectively and stably removed by the manufacturing process, they may be controlled in the process and tests for related residues may not be included in the release test items. For test items that are easily affected by storage processes, highly variable and related to product safety and efficacy, setting of both release specifications and shelf life specifications is recommended. It is encouraged to use advanced physicochemical analytical methods for quality control on the premise that method suitability validation dossiers can be provided. Generally, advanced quality control methods are confronted with great challenges in method suitability validation at different development stages and method transfer between different laboratories. Consideration should be given to differences in method suitability validation between different development stages, and the consistency of test results before and after method transfer should be evaluated using appropriate methods.

When applying for clinical trials, the specification can be preliminarily established based on process verification data; at the marketing stage, risk control analysis should be performed according to the relevant guidelines, and complete specifications as well as methodological validation dossiers should be provided based on process validation results.

(I) Refined polysaccharides

It is recommended to consider the following quality control items: total solid content, identification tests, polysaccharide content, contents of specific groups, molecular size and distribution, residual nucleic acids, residual proteins, residues of other process impurities, bacterial endotoxins, sterility, etc. For refined polysaccharides that are freeze-dried for storage, residual water should be controlled.

For specific groups, the choices of test groups should be justified.

(II) Polysaccharide degradation products

Considering that molecular sizes of degraded polysaccharides are closely associated with the subsequent manufacturing process and the immunogenicity of conjugates. The molecular sizes and distribution of polysaccharide degradation products should be controlled. If it is demonstrated in process development and quality attribute studies that the polysaccharide degradation process has an impact on the contents of specific groups, the contents of the specific groups should be controlled.

With regard to the physical degradation of polysaccharides, viscosity can be defined as a process control measure of the molecular size, and the relationship between viscosity and the molecular size should be studied to provide reference for establishing the viscosity range.

(III) Polysaccharide activation products and derivatives

The effects of chemical modification, i.e., activation degree or derivation rate, should be determined using appropriate methods; additionally, the molecular sizes and distribution of activation products and derivatives can be determined by appropriate methods such as gel filtration or high performance liquid chromatography, so as to ensure the batch-to-batch consistency of polysaccharide-protein conjugation reactions.

(IV) Carrier proteins

If tetanus toxoid and diphtheria toxoid with national standards are used as carriers, their quality attributes should comply with the requirements of the current Pharmacopoeia of the People’s Republic of China. Additionally, the content of monomers should be controlled using such methods as high performance liquid chromatography; the contents of binding sites (e.g., amino content) should be determined using appropriate methods. During methodological validation, consideration should be given to whether the selected method can effectively separate carrier protein monomers and aggregates, and it is also recommended to investigate the assignment of each peak.

If proteins other than those mentioned above are used as carriers, corresponding specifications should be established with reference to the above carrier protein specification requirements and on the basis of respective characteristics and manufacturing processes, e.g., purity, protein content, bacterial endotoxins, residual host DNA, activity/specific toxicity (if applicable), etc. Where recombinant proteins are used as carriers, quality control should be implemented with reference to relevant requirements on recombinant DNA protein products. It is recommended to use two test methods of different principles for quality control.

Where the carrier protein undergoes derivation prior to conjugation, the derivation rate and purity (e.g., monomer content, molecular size and distribution, etc.) should be controlled to ensure batch-to-batch consistency.

(V) Monovalent conjugate bulks

For different polysaccharide conjugate vaccines, different conjugation processes may be used. To ensure the stability safety, efficacy, and batch-to-batch consistency of conjugates, corresponding quality control methods should be established. It is recommended the following quality control items be considered:

1. Identification: Polysaccharide identification tests should be carried out using appropriate methods.

2. Assay: Including polysaccharide content, protein content, etc.

3. Polysaccharide/protein ratio: This measure will influence the immunogenicity, consistency and stability of conjugates and may be defined as an indirect marker of conjugation reactions. If the chemical conjugation reaction process can produce unique conjugation markers (e.g., a specific amino acid), the extent of polysaccharide protein conjugation reaction can be quantitatively analyzed by measuring the markers.

4. Molecular size and distribution: Test methods include Sepharose CL-4B/CL-2B and HPLC-MALLS, which have been admitted in the Pharmacopoeia of the People’s Republic of China. It is encouraged to use advanced methods for release testing of molecular sizes and distribution.

5. Product related impurities: Including but not limited to contents of free polysaccharides, free proteins, etc. For the determination of free polysaccharides, conditions for a valid test should be set, e.g., requirements on the recovery of free polysaccharides for each precipitation procedure. Free protein test methods include SDS-PAGE electrophoresis, HPLC, etc.

6. Process related impurities: Residual impurities with potential safety risks should be included into specifications for control based on the comprehensive consideration of safety risks of impurity residues, process routes and removal effects.

7. Safety indicators: Including sterility test and bacterial endotoxin test.

For multivalent adjuvanted vaccines, if addition of the adjuvant (e.g., adsorption) precedes mixing in the process, the polysaccharide content, free polysaccharide content, adjuvant content, adsorption rate and sterility of the post-adsorption monovalent bulk should be tested.

(VI) Semi-finished products

On the basis of adequate quality studies and process validation, semi-finished products should undergo sterility test.

(VII) Finished products (excluding combined vaccines)

It is recommended the following quality control items be considered: product identity, physicochemical characteristics, assay, safety indicators, biological activity, etc. For freeze-dried dosage forms, the reconstitution diluent should be tested. For combined vaccines, tests should be carried out with reference to relevant guidances.

1. Identity: Typically immunological assays are carried out using polysaccharide specific antibodies.

2. Physicochemical properties: Including appearance, pH value, loading amount, osmolality, molecular size and distribution. For a freeze-dried product, water should be controlled.

3. Assay: contents of polysaccharides of different types, total protein content, free saccharide content, bound antigen content, bound protein content, contents of excipients. If adjuvants are used, the contents of adjuvants and the adsorption rate should be controlled.

4. Safety indicators: Typically including endotoxins, abnormal toxicity, sterility test, etc.

5. Biological activity test: In view of the significant variability of animal in vivo immunogenicity test methods, it is reference vaccines be set and specification limits be proposed by appropriate ratio methods. The sensitivity of different polysaccharide protein conjugate vaccines to experimental animals varies. It is recommended to reasonably select test animals, immunization schedules and immunization doses based on prior knowledge, pharmacodynamic studies, etc.

(VIII) Analytical method development and validation

Applicants should select appropriate analytical methods based on product characteristics and process characteristics of polysaccharide conjugate vaccines. For varieties with multiple types and low saccharide contents, physicochemical and immunological methods may be used separately or in combination for comprehensive quality control. The testing of both bulks and finished products involves sample pretreatment, e.g., precipitation of free saccharides, desorption of adjuvants, hydrolysis of polysaccharides into specific monosaccharides, etc. The pretreatment process may introduce systematic errors. In principle, it should be ensured that the pretreatment process can maintain the inherent state of the product or reflect the original state of the product and yield an acceptable recovery rate. When necessary, in-house criteria for valid tests should be established. It is encouraged to use advanced methods for quality control, e.g., NMR for controlling polysaccharide identity, specific groups and impurities; HPLC for determining residual process related impurities; and HPLC-MALLS for controlling molecular size and distribution.

For methods in the Pharmacopoeia of the People’s Republic of China, the suitability should be verified upon assessment. Following comprehensive validation, self-established methods should, depending on the test purpose and analyte, be verified and validated in terms of accuracy, precision (including repeatability, intermediate precision and reproducibility), specificity, limit of detection, limit of quantitation, linearity, range and robustness.

When applying for clinical trials, the provided methodological validation dossiers should preliminarily verify the suitability of the test method; analytical method development and validation should be refined following the continuous deepening of product development and studies; at the marketing stage, comprehensive methodological validation dossiers should be provided in accordance with relevant guidelines. If methodological changes or transfers occur during development, corresponding methodological bridging studies should be carried out.

1. Molecular size and distribution

Appropriate methods should be selected based on product characteristics and manufacturing processes to objectively reflect molecular weights and distribution. The used methods should promise sufficient resolution within an appropriate molecular weight range. Due to the characteristics of continuous molecular weight distribution of products from different process stages (polysaccharides, activated polysaccharides, certain protein carriers, conjugates, etc.), consideration should be given to the resolution range of the methods and the applicability to test products as well as product resolution validation for the determination of molecular weights and distribution.

With regard to methods characterizing molecular weights and distribution based on the Kd value and its recovery, Kd margins that can sensitivity reflect batch-to-batch consistency of products should be selected. Additionally, it is recommended to carry out studies and accumulate data on the Kd value corresponding to 50% of the peak area.

For test methods measuring weight average molecular weights based on SEC-MALLS, consideration should be given to the effects of polysaccharide structures and purity on dn/dc, and studies on the correlation between this method and methods in the Pharmacopoeia of the People’s Republic of China should be conducted.

For multivalent vaccines, as monovalent conjugate antigens cannot be separated and the contents are low, total antigen molecular size determination methods can be employed to reflect the total antigen stability. If necessary, monovalent bulk specific molecular size determination methods should be developed.

2. Polysaccharides

Generally chemical methods and immunological methods are included. Consideration should be given to the following aspects: (1) Chemical methods include particle chromatography (etc.), which is mostly used for conjugate vaccines for use with fewer doses and where the calculation is based on polysaccharide specific functional groups. Consideration should be given to the hydrolysis and elution of specific monosaccharides or chemical groups in various antigens as well as the selection of reference standards; the calculation formulas for corresponding types should be specified; use of specific correction factors should be justified. (2) Immunological methods include ELISA, rocket electrophoresis, rate turbidimetry, etc. If immunological methods are used, consideration should be given to the specificity of serum, the standardization and quality control of serum, and the traceability during serum replacement. It is recommended to establish sufficient standard serum libraries at the early stages of development to support the commercial production. (3) For monovalent conjugate bulks, generally polysaccharide contents are determined by chemical methods. For finished products of multivalent polysaccharide conjugate vaccines, polysaccharide contents are often determined by immunological methods. Considering the systematic differences in polysaccharide content determination results between the two kinds of methods, it is recommended to conduct sufficient research and accumulate data on the correlation between the two kinds of methods at the early stage of development, so as to avoid differences in formulation points between products to be marketed and confirmatory clinical batches due to use of different methods. (4) Test methods for antigen contents in finished products are susceptible to interference from freeze-drying protectants, aluminum adjuvants and surfactants. Typically antigen separation is required prior to determination, and effects of pretreatment including desorption should be validated.

3. Free saccharides

For conjugate bulks, sodium deoxycholate method, high salt and high alcohol precipitation method and aluminum hydroxide gel binding method are frequently used for separating free polysaccharides and conjugated polysaccharides; for multivalent products, due to such factors as low contents and interference from adjuvants and components, part methods for determining free polysaccharides in product bulks are not applicable to finished products. For freeze-dried vaccines, the contents of finished products can be enriched by reducing the reconstitution value to detect free polysaccharides and free proteins. For multivalent liquid/adjuvant-adsorbed vaccines with low antigen contents, test methods for free polysaccharides and free proteins should meet corresponding limit of quantitation or limit of detection requirements. Consideration should be given to the effects of different pretreatment methods on test results, and it is recommended to control the conditions for valid methods; the methodological suitability should be verified through methodological validation such as spiked tests, and the validation should be performed with incorporation using samples consistent with residual levels.

4. Bound antigen/bound protein

They are used for characterizing the total adsorption rate and total conjugation rate. The separation effects of adsorbed components and non-adsorbed components should be validated. Methods for determining contents of supernatants or precipitates are both acceptable. If test methods are different from total antigen or protein test methods, it should be demonstrated that the method differences do not affect test results.

5. Residues

It is encouraged to use more sensitive methods such as chromatography for studying relevant residues. In accuracy validation, standard materials equivalent to the actual product concentrations should be added for validation.

6. Test serum

Test serum is used for product process development and quality control method development. It is one of the key factors for successful product development. Consideration should be given to the characterization of the polysaccharide antigen epitope retention capacity, specificity, titer, batch-to-batch consistency, reserve and storage stability. Whenever possible, high quality antigens should be used for serum preparation. Multivalent vaccine serum is prone to cross reactions with antigens, which can be reduced by appropriate purification or cross adsorption to ensure specificity. Quality control should be carried out for standard serum titers (or specific antibody contents), as low-titer serum often cannot meet the requirements for quantitative determination of multivalent vaccine antigens. Enterprises should establish and reserve sufficient test serum and adopt appropriate storage conditions to ensure that testing requirements are met within the expiration date.

(IX) Standard materials

Standard materials can be established and prepared with reference to requirements of the Pharmacopoeia of the People’s Republic of China and other relevant guidelines. If international/national standard materials are used, information about used standard materials (source, batch, verification, etc.) should be clearly specified. For self-made standard materials, studies should be conducted on the preparation process, standardization, stability, etc. It is recommended to establish standard materials for critical quality attribute tests using pivotal clinical trial batches and pay attention to studies on the traceability of standard materials.

Due to the existence of multiple intermediate products and multiple test methods, multiple types of standard materials are involved in the testing of polysaccharide conjugate vaccines. For intermediates or finished products that exist as a single component, corresponding substances with single components or similar characteristics can be selected as standard materials. With regard to standard materials for the determination of polysaccharide antigen contents in finished products of multivalent vaccines, if chemical methods are used for determination, the standard materials should have the same chemical reaction characteristics as the antigens; if polysaccharide contents are determined by ion chromatography, monosaccharides should be used as standard materials when polysaccharides in the conjugates can be completely hydrolyzed into monosaccharides, and polysaccharides may be considered as standard materials when polysaccharides in the conjugates cannot be completely hydrolyzed into monosaccharides. If immunological methods are used, standard materials should maintain stable antigenicity to ensure their stability in antigen-antibody binding reactions. When antigens containing polysaccharides are used as standard materials, appropriate methods should be used to assign values to antigen contents. Appropriate standard materials should be selected. If international standard materials or national standard materials are available, relevant standardization is recommended.

If use of standard materials is needed in determining molecular sizes of antigens, stable polysaccharides should be selected, and the stability investigated. If bridging with Kd values specified in the Pharmacopoeia of the People's Republic of China is needed, bridging validation data should be provided.

VII. Stability Studies

Stability studies for polysaccharide conjugate vaccines should follow the Guideline for Stability Testing of Biological Products in the Pharmacopoeia of the People’s Republic of China, the Technical Guideline on Stability Studies for Biological Products (Interim) and relevant ICH guidelines and comply with relevant requirements in the “Procedure for the Storage and Transportation of Biological Products” in the Pharmacopoeia of the People’s Republic of China. Comprehensive stability testing should be completed before the marketing application is submitted. Appropriate packaging materials should be selected, storage and transportation conditions should be specified, and reasonable shelf lives should be established.

The stability study protocol should be designed based on dosage form characteristics, manufacturing processes and clinical medication regimens of polysaccharide conjugate vaccines. In general, long-term testing, accelerated testing, stress testing, shipping stability testing and in-use stability testing (especially when freeze-dried independent packages are used for part types) should be included. Study conditions should fully account potential situations in future manufacture, storage, transportation and use.

Stability studies for polysaccharide conjugate products include intermediates to be held, e.g., purified polysaccharides, degraded/derived polysaccharides, carrier proteins, conjugate bulks, as well as semi-finished products and finished products, which should be fully tested at key time points. In addition to release test items, other investigational sensitive measures should be selected based on product characteristics, e.g., molecular size and distribution and specific groups for intermediate products; adsorption rate, bound antigen, bound protein and in vivo efficacy test for finished products.

To facilitate comparability studies on changes during clinical development or post-marketing changes, accelerated stability studies should be conducted on all intermediate products apart from long-term stability. As many intermediate products are involved in the production of polysaccharide conjugate vaccines, if storage at multiple stages is involved, cumulative stability testing should be conducted.

VIII. Primary Packaging Materials and Containers

All consumables (such as chromatography fillers, filters, cassettes, liquid storage bags, liquid transfer pipes, etc.) and packaging systems used in the production of polysaccharide conjugate vaccines that come into contact with the products should have stable physical and chemical properties and good compatibility with intermediate products and solutions they come into direct contact with. Studies on the compatibility of packaging materials at each manufacturing stage should be conducted in accordance with domestic and foreign relevant guidelines or other applicable supporting dossiers should be provided; when submitting the marketing application, study dossiers on the compatibility between commercial products and packaging materials should be provided.

IX. Glossary

Carrier protein: a protein that covalently binds to bacterial polysaccharide antigens using chemical methods or other techniques to enhance antigen-T cell-dependent immune responses.

Polysaccharide degradation: the process of processing natural polysaccharides using physical, chemical, or biological methods to break the sugar chains. The resulting products are referred to as polysaccharide degradation products.

Activation: the process of generating polysaccharides or proteins with chemical reactivity through activation reactions. The resulting products are referred to as activation products.

Derivation: the process of linking molecules with reactive activity to polysaccharides or proteins. The resulting products are referred to as derivatives.

Process characterization: the process of systematically studying the effects of process parameters on product quality and process performance to develop complete process control strategies, so as to ensure the manufacturing process stability and product consistency.

Process robustness: The manufacturing process is influenced by variations in raw materials, process equipment, process operation parameters, environment, and human factors. Process robustness refers to the ability of the process to withstand the effects of these factors without adversely affecting product quality.

Specific group: a chemical group connected on molecular skeletons or side chains of polysaccharides, that determines the specificity of polysaccharide groups/types, e.g., O-acetyl, methyl, etc.

X. References

[1] 国家药典委员会.《中华人民共和国药典》(2020 年版). 2020.

[2] CDE. 结合疫苗质量控制和临床研究技术指导原则. 2005.

[3] ICH Q5D. Derivation and Characterisation of Cell Substrates Used for Production of Biotechnological/Biological Products. [EB/OL]. [1997].

[4] ICH Q11. Development and Manufacture of Drug Substances. [EB/OL]. [2012].

[5] CDE.《预防用含铝佐剂疫苗技术指导原则》.2019.

[6] WHO EXPERT COMMITTEE ON BIOLOGICAL STANDARDIZATION (51st WHO TRS N°897 (A1): 2000) Recommendations for the production and control of Haemophilus influenzae conjugate vaccines.

[7] WHO EXPERT COMMITTEE ON BIOLOGICAL STANDARDIZATION (57th report: WHO TRS N°962 (A2): 2006) Recommendations to assure the quality, safety and efficacy of group A meningococcal conjugate vaccines.

[8] WHO EXPERT COMMITTEE ON BIOLOGICAL STANDARDIZATION (55th report: WHO TRS N°924 (A2): 2004) Recommendations for the production and control of group C meningococcal conjugate vaccines.

[9] WHO EXPERT COMMITTEE ON BIOLOGICAL STANDARDIZATION (60th report: WHO TRS N°927 (A2): 2009) Recommendations to assure the quality, safety and efficacy of pneumococcal conjugate vaccines.

[10] CDE. 生物制品稳定性研究技术指导原则(试行). 2015.

[11] The United States Pharmacopeial Convention. 《VACCINES FOR HUMAN USE-POLYSACCHARIDE AND GLYCOCONJUGATE VACCINES》. 2017.

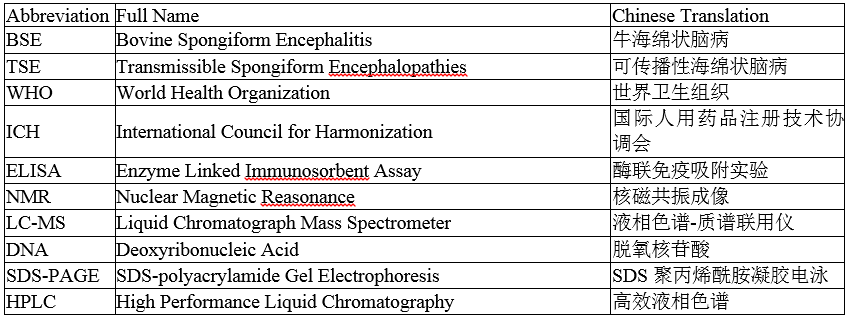

XI. List of Abbreviations

News

News

Position :

Position :